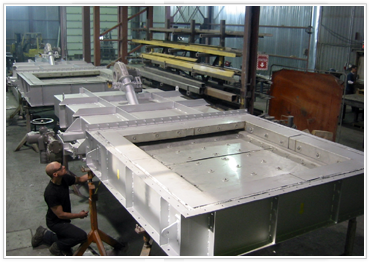

Guillotine Dampers

Guillotine dampers are single-bladed dampers that are best suited for applications where flow isolation is fundamental and pressure drop must be minimal. Unlike louver and butterfly dampers that have blades that remain within the gas path during normal operation, guillotine dampers have fully retractable blades and therefore cause no pressure drop in the system.

METCO TECHNOLOGIES INC. guillotine dampers utilize a heavy-duty rack and pinion drive mechanism to move the blade back and forth. Depending on site constraints, the racks can be mounted at various locations to offer the most economical option for our customers while being able to work within the required footprint. For smaller sized guillotine dampers, the use of pneumatic cylinders instead of racks can be used to accomplish a quicker speed of operation as well as reduced cost.

For environments where leakage to atmosphere is unacceptable or ingress of ambient air to process is unacceptable, METCO TECHNOLOGIES INC. can offer a completely sealed bonnet that will encapsulate the blade when the damper is in the open position, eliminating any possibility of any leakage to and from the environment.

For applications where complete isolation of the ductwork is required, the use of a seal air fan in combination with high-flex seals will assure that guillotine damper is 100% leak-free.

For applications where internal insulation or refractory is required METCO TECHNOLOGIES INC. can assure that the design used will meet industry standards.

Depending on the application and the sealing requirements, METCO TECHNOLOGIES INC. can assist in determining the best seal selection for your damper.

Seal Configurations:

- No seals

- Composite tadpole seals

- Metal-to-metal seals

- Purging seals

- High-flex metallic seals

Operator selection is another key decision where METCO TECHNOLOGIES INC. can assist our customers.

Operator Types:

- Manual

- Pneumatic actuation

- Electric actuation

- Hydraulic actuation

Each of these types of actuation have advantages and disadvantages. Some important information required to assist in the decision process are as follows:

- Torque / thrust required

- How quickly the damper must be able to fully open/shut?

- What is the available power source (instrumentation air, electrical power, etc.)?

- What are the environmental conditions surrounding the actuator?

- Is a failsafe system required to force the damper to move to a desired position if power or signal is lost or removed?

- Power consumption

METCO TECHNOLOGIES INC. can assist you in determining the best option for your needs in order to minimize upfront damper costs as well as operational costs down the road.

Guillotine dampers are available for rectangular, square and circular duct sections.