TYPICAL PROFILES

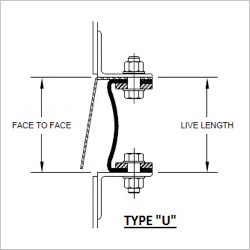

The Type “U” design is a molded belt design as can be seen in the adjacent image.

The Type “U” design is a molded belt design as can be seen in the adjacent image.

This is typically a more economical option as no steel frame is incorporated as part of the expansion joint scope.

This type of expansion joint requires more work on site for installation than a traditional fully assembled expansion joint as per the “C”, “H”, “O” and “T” models shown below.

This model is available with and without liner.

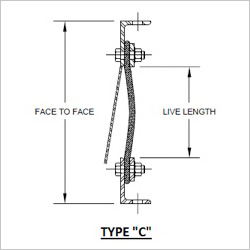

The Type “C” design is a flat belt design as can be seen in the adjacent image.

The Type “C” design is a flat belt design as can be seen in the adjacent image.

This is one of the most common expansion joints in the general air handling industry. This model is generally used for applications of clean gas subjected to temperatures below 500 °F (260 °C). The two flange frames come with bolt pattern to match existing ductwork flanges making for ease of installation. This design also lends itself well to belt replacement on site.

This model is available with and without liner.

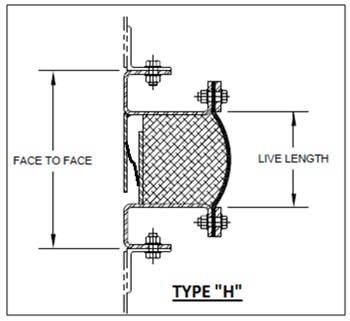

The type “H” design is a flat belt design as can be seen in the adjacent image.

The type “H” design is a flat belt design as can be seen in the adjacent image.

This expansion joint model, also very commonly used, allows operation at elevated temperatures (+1 000 °F (588 °C)) as well as the ability to be used in some dirtier environments. The insulation pillow fills the cavity between the liner and flexible belt and protects the belt from abrasion and elevated temperatures. The pillow is constructed of fiberglass or ceramic fiber insulation encased in a woven high temperature cloth and/or stainless steel wire mesh.

This model is available with and without liners as well as with and without insulation pillow.

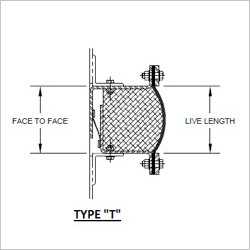

The type “T” design is a flat belt design as can be seen in the adjacent image.

The type “T” design is a flat belt design as can be seen in the adjacent image.

This expansion joint model allows operation at elevated temperatures (+1 000 °F (588 °C)) as well as the ability to be used in some dirtier environments. The insulation pillow fills the cavity between the liner and flexible belt and protects the belt from abrasion and elevated temperatures. The pillow is constructed of fiberglass or ceramic fiber insulation encased in a woven high temperature cloth and/or stainless steel wire mesh.

Unlike the Type “H” model above, this model has a varied frame design which can be used in applications where both flange connections are not exposed to the same temperatures (hot flange and cold flange). This design also requires more belt and insulation pillow material in order to accomplish the same movements as a Type “H” expansion joint. This could be cost advantageous for applications where the frame material would require the use of an alloy material.

This model is available with and without liners as well as with and without insulation pillow.

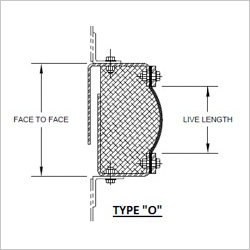

The type “O” design is a flat belt design as can be seen in the adjacent image.

The type “O” design is a flat belt design as can be seen in the adjacent image.

This expansion joint model allows operation at elevated temperatures (+1 000 °F (588 °C)) as well as the ability to be used in some dirtier environments. The insulation pillow fills the cavity between the liner and flexible belt and protects the belt from abrasion and elevated temperatures. The pillow is constructed of fiberglass or ceramic fiber insulation encased in a woven high temperature cloth and/or stainless steel wire mesh.

Unlike the Type “H” model above, this model has a varied frame design which can be used in applications where both flange connections are not exposed to the same temperatures (hot flange and cold flange). This design also requires more belt and insulation pillow material in order to accomplish the same movements as a Type “H” expansion joint. This could be cost advantageous for applications where the frame material would require the use of an alloy material.

Additionally, unlike the Type “T” model above, this model has belt connecting flanges pointing inwards allowing for easy installation of the expansion joint between existing ductwork. This model also reduces the required belt width for the same face-to-face dimension which translates into cost savings. The disadvantage of this model is the welded nut design holding the flexible belt in place making it more difficult for belt replacement. This model also allows for lesser movements then the Type “T” model due to the reduction in live length.

This model is available with and without liners as well as with and without insulation pillow.

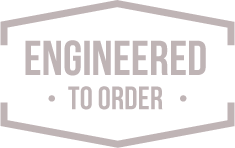

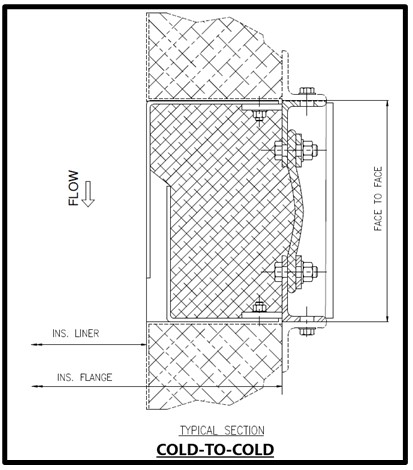

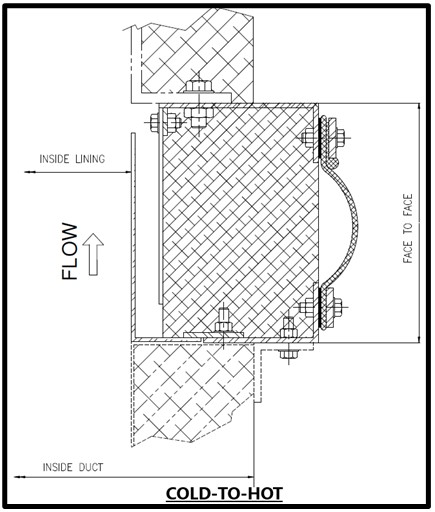

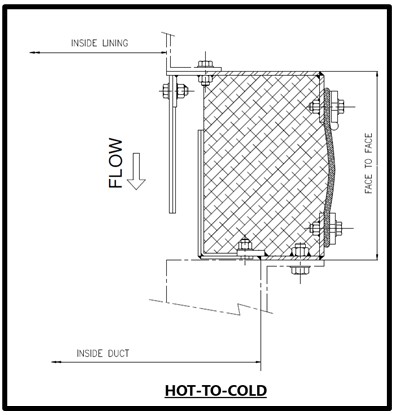

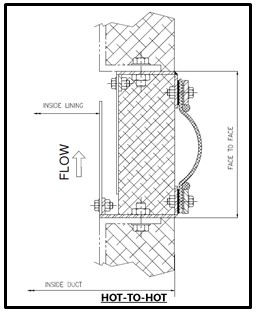

Gas Turbine Exhaust Expansion Joint Designs

Designed specifically to address the elevated temperatures, abrupt temperature changes and to accommodate “HOT” and “COLD” flange designs that are common with gas turbine exhaust systems.

Many other derivations of these main profiles are available given the existing duct configuration.